AAC blocks

Suryshree AAC Blocks – Your Trusted Source for Sustainable, High-Performance Building Solutions!

AAC blocks

AAC or Autoclaved Aerated Concrete was developed by Swedish architect J Axel Eriksson in 1923. The key features that it possessed at that time was providing structure, insulation and resistance to mold and fire. Over the years this design has been improved to provide and array of different features like pest resistance and superior strength. Initially what was used for just industrial purposes now can be used for a lot more including residential purposes too.

AAC blocks much like carbon fiber; light and strong. AAC blocks have the tendency to float on water and at the same time the ability to withstand tremendous pressure from storms as well as earthquakes.

1. Suryshree Sand Base Blocks

Sand-Based Blocks are versatile and durable building materials designed for a range of construction applications. Made from a blend of sand, cement, and aggregates, these blocks offer excellent strength and stability for both residential and commercial structures. Their high compressive strength makes them ideal for load-bearing walls, while their thermal insulation properties contribute to energy efficiency and comfort. Sand-based blocks are easy to handle and work with, providing a reliable solution for building projects that require robust and long-lasting materials. Whether used for walls, partitions, or other structural elements, sand-based blocks combine performance with cost-effectiveness, ensuring a solid foundation for any construction endeavor.

Key Feature

High Compressive Strength

Provides robust support for load-bearing walls and structural elements, ensuring durability and stability..

Thermal Insulation

Offers effective insulation, helping to regulate indoor temperatures and improve energy efficiency in buildings.

Durability

Resistant to weathering, erosion, and impact, making it suitable for both internal and external applications.

Ease of Handling

Lightweight and easy to work with, allowing for straightforward installation and reduced labor costs.

2. Suryshree flyash Base Blocks

Fly Ash Blocks are innovative and eco-friendly building materials made from fly ash, a byproduct of coal combustion, combined with cement and aggregates. These blocks offer exceptional strength, lightweight properties, and superior thermal insulation, making them an ideal choice for modern construction. Fly ash blocks are highly durable, resistant to weathering, and have excellent fire resistance, contributing to both safety and longevity in building structures. Their use supports sustainable building practices by recycling industrial byproducts and reducing the environmental impact of traditional construction materials. Easy to handle and install, fly ash blocks provide an efficient and cost-effective solution for creating sturdy and energy-efficient walls and partitions.

Key Feature

High Strength

Provides excellent compressive strength and load-bearing capacity, ensuring robust and durable construction.

Lightweight

Lighter than conventional blocks, which reduces transportation and handling costs and simplifies the construction process

Superior Thermal Insulation

Offers enhanced insulation properties, helping to regulate indoor temperatures and improve energy efficiency.

Fire Resistance

Demonstrates high fire resistance, contributing to the overall safety and fire protection of buildings.

Applications

AAC Blocks are perfect for residential buildings, offering excellent thermal insulation, soundproofing, and lightweight strength. They enhance indoor comfort, reduce energy bills, and speed up construction, making them a smart and cost-effective choice for modern homes.

Applications

AAC Blocks are well-suited for industrial complexes due to their high fire resistance and load-bearing capacity. They provide superior thermal insulation, helping regulate internal temperatures and reduce energy consumption in large-scale facilities.

Applications

AAC Blocks are an excellent choice for retail centers, offering robust strength, effective sound insulation, and rapid installation for timely project delivery. Their thermal and acoustic properties create a more comfortable shopping environment for visitors.

Applications

AAC Blocks are ideal for storage occupancies, offering exceptional thermal insulation to help maintain consistent indoor temperatures. This stability is crucial for protecting sensitive goods in warehouses and storage facilities.

Applications

AAC Blocks are ideal for commercial buildings like offices, hotels, and restaurants, offering energy-efficient, sound-insulated walls that enhance comfort and professionalism. Their excellent thermal performance also helps lower energy usage and operational cost.

Applications

AAC Blocks are highly suitable for institutional buildings such as hospitals and educational facilities, thanks to their fire resistance and non-toxic composition. They support healthier indoor environments, while their insulation properties enhance energy efficiency and long-term safety.

Manufacturing

how AAC Blocks are manufacture

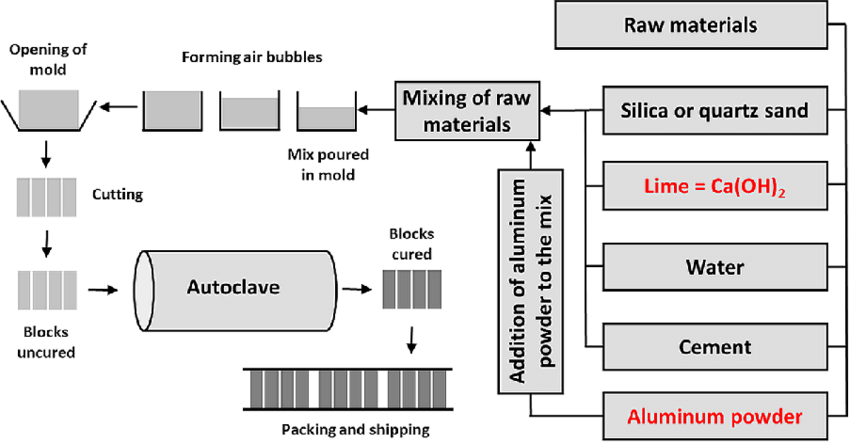

AAC blocks are made from portland cement, silica rich material like fly ash or sand, lime, water and aluminum powder as an expansion agent. The production process of AAC blocks is very carefully monitored to insure a controlled consistency in the proportions and timing of all ingredients that are used in each batch. The materials are first mixed into a slurry and then poured into large moulds where the expansion agent reacts with the alkalis in the cement and lime to produce millions of small hydrogen gas bubbles. The mix expands and rises almost 2 times its initial volume. The hydrogen evaporates and the ‘cake’ sets up and hardens into a stable closed cell matrix which can then be precision wire-cut into blocks or panels. The green aerated concrete is then steam cured in a pressurized autoclave for about 12-14 hours where upon it undergoes a second chemical reaction and transforms into the mineral Tobermorite or calcium silicate. The finished materials are palletized and delivered by truck directly to the job site. Very first step of AAC blocks manufacturing process is raw material preparation. List of raw materials and relevant details are mentioned below.

Raw Material Preparation

Mixing Ingredients: The primary raw materials used in AAC block manufacturing are fly ash or sand, lime, cement, gypsum, and aluminum powder. These materials are accurately measured and mixed together in a large mixer.

Grinding: If sand is used instead of fly ash, it is ground into a fine slurry to ensure uniformity and consistency in the final product

Slurry Preparation

Mixing with Water: The dry mix is combined with water to create a slurry. Aluminum powder is then added to this slurry, which reacts with the other ingredients to produce hydrogen gas. This gas forms tiny bubbles throughout the mixture, causing it to expand and rise, similar to how yeast makes bread dough rise.

Pouring and Molding

Casting: The slurry is poured into large molds, where it begins to expand due to the gas bubbles. This expansion increases the volume of the mixture, creating the characteristic porous structure of AAC blocks.

Pre-curing: The molds are left to rest for several hours, allowing the slurry to solidify into a semi-solid “cake.” During this period, the hydrogen gas escapes, and the mixture begins to harden.

Cutting

Cutting into Blocks: Once the cake has reached the desired firmness, it is removed from the molds and cut into blocks of specific sizes using precision wire-cutting machines. These machines ensure that each block has accurate dimensions, minimizing waste and making the blocks easier to handle during construction.

Autoclaving

High-Pressure Steam Curing: The cut blocks are then transferred to an autoclave, a large pressure vessel where they are cured under high pressure and temperature. This process, known as autoclaving, typically involves subjecting the blocks to steam at temperatures of around 180°C (356°F) and pressures of approximately 12 bars for several hours.

Formation of Calcium Silicate Hydrate: During autoclaving, the lime reacts with the silica in the sand or fly ash to form calcium silicate hydrate, which gives the blocks their strength and stability.

Final Processing

Cooling and Storage: After autoclaving, the blocks are allowed to cool and then moved to storage areas for further curing if needed. This final curing phase helps to ensure the blocks have reached their full strength.

Quality Control: Each batch of AAC blocks undergoes rigorous quality control tests to ensure they meet the required standards for density, strength, and dimensional accuracy.

Packaging & Dispatch

Packaging: The blocks are carefully packed to prevent damage during transportation.

Dispatch: Finally, AAC Blocks are loaded and dispatched to various construction sites.

frequently asked questions

AAC blocks are lightweight, precast foam concrete building materials made with cement, lime, sand, water, and an expansion agent. They're known for thermal insulation and easy handling.

Yes, AAC blocks have good compressive strength (3–4.5 MPa) and can be used for low- to mid-rise load-bearing structures.

Absolutely. AAC blocks offer excellent fire resistance—up to 4–6 hours depending on thickness.

AAC blocks are lighter, offer better insulation, and reduce construction time and labor compared to traditional red bricks.

Yes, but proper waterproofing and external plastering are essential since AAC is porous and can absorb moisture if untreated.

Yes. Although costlier per unit, they lower overall project costs by reducing structural load, mortar usage, and labor.

Thin-bed cement-based mortars or adhesive glue are commonly used, requiring less quantity than traditional mortar.